Description

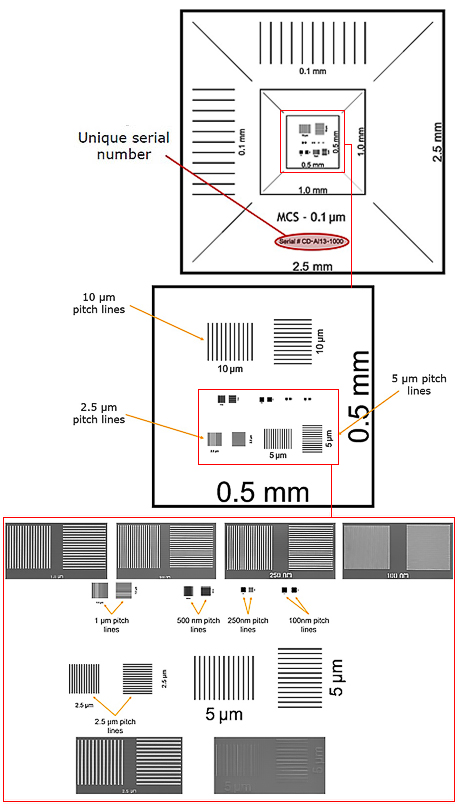

EM-Tec MCS X-Y series SEM magnification calibration standards

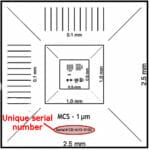

bidirectional X-Y SEM calibration standard with 2.5mm to 1 µm or 100nm patterns

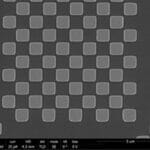

The EM-Tec MCS X-Y series calibration standards share the same calibration range and MEMS manufacturing technology as the EM-Tec MCS series magnification calibration standards. These fully featured bi-directional calibration standards offer adjacent calibration pattern in both and X and Y direction. They are ideal for magnification calibration or critical dimension measurements in table top SEM, standard SEM, FESEM, FIB, Auger, SIMS and reflected light microscope systems.

Two types of calibration ranges for the Em-Tec MCS X-Y calibration standards are offered, both calibration ranges with certificate of traceability or with an individual certificate of calibration:

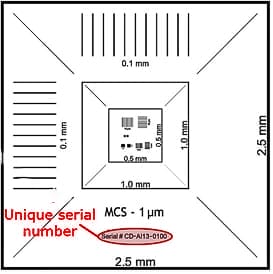

- EM-Tec MCS-1-XY with X-Y scales ranging from 2.5mm to 1µm; ideal for table top and compact SEMs, covers the 10x to 20,000x magnification range.

We offer a traceable and a certified version - EM-Tec MCS-0.1-XY with X-Y scales ranging from 2.5mm down to 100nm; ideal for SEM, FESEM and FIB systems, covers 10x to 200,000 magnifications.

We offer a traceable and a certified version

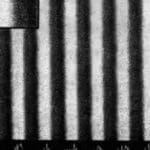

The features on the EM-Tec MCS X-Y series are made using state of the art MEMS manufacturing techniques with high contrast chromium deposited lines for the larger features and gold over chromium for the smaller features below 2.5µm. The gold deposited features ensure optimum signal to noise ratio for calibration purposes. Advantages of the EM-Tec MCS X-Y series are:

- unprecedented precision over the full calibration range in both X and Y direction

- all X-Y features in one single ultra-flat plane

- metal on silicon with excellent signal to noise ratio

- wider range of features to accurately calibrate low, medium and high magnification ranges

- compatible with both SE and BSE imaging

- fully conductive materials

- easy to convert X-Y metric feature sizes

- can be cleaned with plasma cleaning

- all NIST traceable or optionally certified

The EM-Tec MCS-0.1 calibration standard is an excellent replacement for the discontinued SIRA calibration standard (which was using only 0.51 and 0.463µm features) with added advantages. Compatible feature sizes for the SIRA standard are 50µm (5×10µm) and 0.5µm (500nm).

Specifications for the EM-Tec MCS series calibration standards

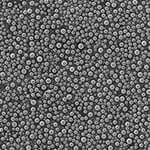

| Substrate | 525µm thick boron doped ultra-flat wafer with <100> orientation |

| Conductive | Excellent; 5-10 Ohm resistivity |

| Pattern size | 2.5 x 2.5mm |

| Chip size | 4 x 4 mm (unmounted) |

| Features MCS-1-XY | 2.5, 1.0, and 0.5mm both in X and Y direction 250, 100, 10, 5, 2.5 and 1µm both adjacent in X and Y direction |

| Features MCS-0.1-XY | with additional 500, 250 and 100nm both adjacent in X and Y direction |

| Features material | 50nm Chromium for feature sizes 2.5mm to 2.5µm 50nm Gold over 20nm Chromium for size 1µm to 100nm |

| Traceable uniformity | 0.2% or better |

| Certified uniformity | 0.03% |

| Traceable uncertainty | 0.7% or better |

| Certified uncertainty | 0.09% |

| Traceability | Wafer level NIST traceability; average data measured on each production wafer |

| Certified | Optional; each certified EM-Tec MCS standard is individually calibrated against a NIST measured standard |

| Application | SEM, FESEM, FIB, Auger, SIMS and reflected light microscopy |

| Identification | Product ID with serial number etched |

| Mounting | Mounting available on popular SEM stubs |

| Supplied | Unmounted: supplied in a Gel-Pak box |

Avis

Il n’y a pas encore d’avis.